FAQ Search

All FAQs

The Caswick Riser Frame (Patent applied for) blocks the open manhole during construction. It provides a raised, bright, visual warning of the manhole presence and prevents pedestrians or vehicles falling into the open manhole. It also prevents debris falling into the pipeline.

During construction, the Caswick Riser Frame acts as a liner ensuring correct alignment of seating rings or brickwork and acts as a former for concrete pouring.

The Caswick Riser Frame can be cut to height once the manhole access is ready to be exposed.

Contact Caswick for more information.

The transition from ground level into the manhole chamber on entry and vice versa on exit is a critical part of safe working in a confined space.

Most specifications stipulate that the distance from ground level to the top of the first step should be a maximum of 675mm (BS EN752, Sewers for Adoption 8th Edition pre-implementation version, Highway Construction Details, Welsh standards for new gravity foul sewers and lateral drains). Sewers for Scotland 3rd Edition requires the distance to be no less than 500mm and no more than 700mm. Within these documents, there are different requirements relating to the minimum number of courses of “adjusting” brickwork between the cover slab and the manhole cover and frame. When the manhole is constructed, the number of courses used can affect the actual distance to the first step.

To assist safe access into and egress from manholes and other chambers, the use of a handhold is strongly recommended. Handholds are not always included as part of the manhole construction and their omission may place operatives at greater risk. Specifiers are advised to consider handholds as an integral part of the manhole design.

Caswick offer handholds in various sizes, fixing methods and materials. The handhold remains fully within the chamber when not in use and can be easily raised into position once the access cover has been removed. The handhold is locked into position and used to provide stability to the person as they transition from the surface level onto the steps in the chamber. When extended, the handhold also creates a visual aid to indicate the location of the manhole to other people in the area.

Once work is complete and the operative is out of the chamber, the handhold is lowered back into the chamber beneath the level of the surface until it is required again. The Caswick handhold connects directly onto Caswick steps and does not require tools to operate it once it has been installed. The handhold remains fully within the chamber.

Contact Caswick for more information.

To deter unauthorized access, some clients specify that permanently fixed steps or ladders should not be used. In these situations, authorized access is commonly made by winch or removable ladders.

Whilst this approach may generally be considered acceptable for authorised access, a secondary means of escape is still required and if unauthorized entry occurs, it is possible that individuals may get into greater difficulty and it will be impossible to escape.

Caswick recognises this problem and has developed a specially designed grating (Patent applied for) which can be used with steps or ladders in preference to winch-only access and is fitted below the manhole cover. The grating prevents unauthorized or accidental entry arising, for example if the cover has been displaced during storm surcharge conditions or through theft and can also be locked to prevent unauthorized access.

Contact Caswick for more information.

Establishing a healthy and safe working environment for lone workers can be different from organising the health and safety of other employees. It will often be safe to work alone. However, the law requires employers to think about and deal with any health and safety risks before people are allowed to do so.

HSE advises that a risk assessment should help employers decide on the right level of supervision. There are some high-risk activities where at least one other person may need to be present. Examples include:

- working in a confined space, where a supervisor may need to be present, along with someone dedicated to the rescue role

It is recommended in EN752 that steps and fixed ladders should not protrude into the flow under normal design flows. Where steps are provided in the side of the channel, recessed toe holes should be used in association with hand holds.

Precast manholes for the UK market have a design life in excess of 100 years in normal conditions of use. In such conditions and when installed in accordance with the manufacturer’s guidelines, Caswick standard steps and ladders are expected to perform their original design function for a similar period. The use of products that do not comply with the minimum requirements of BS EN 13101 (Steps) and BS EN14936 (Ladders) may not be expected to last as long and are more likely to require replacing during the service life of the manhole. Products that only marginally conform with the minimum requirements of BS EN13101 and BS EN14396 may also have a shorter life expectancy compared with standard Caswick steps and ladders.

All respectable manufacturers should be able to provide full documentation on request to show how their products have been assessed and provide evidence to demonstrate how the results of such assessments are deemed to comply with the relevant Standards and industry specifications. Where products have been evaluated by an independent third party, these should be supported with an assessment report and certificate issued and verified by the third party and a record kept in the accreditation body’s Register.

Compliance with the key Product Standards BS EN13101 (Steps) and BS EN14396 (Ladders) should be set as the lowest benchmark of performance. Use of any product failing to meet the minimum requirements may expose users to unacceptable health and safety risks and if done so knowingly, may also represent a failure to comply with the relevant legislation incurring a variety of penalties including fines and imprisonment.

It is highly likely that use of non-compliant products not only leads to added health and safety risks but will also offer a shorter service life and poorer whole life value.

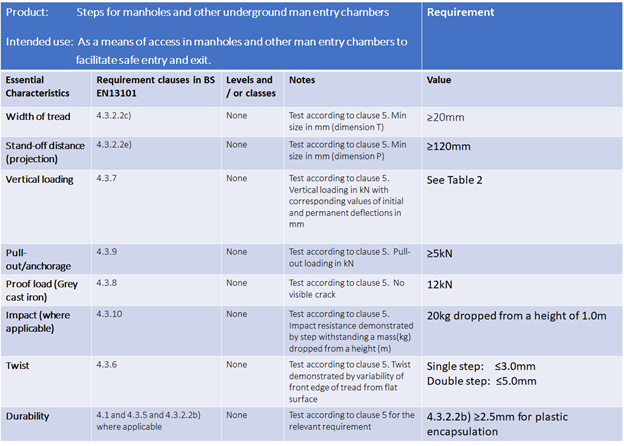

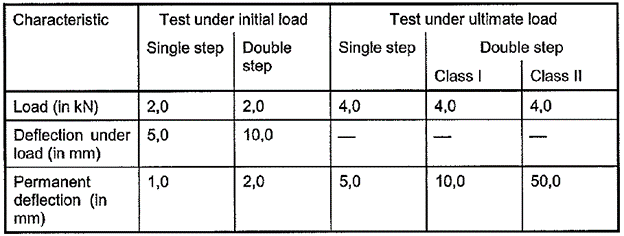

Steps

BS EN13101:2002 Steps for underground man entry chambers. Requirements, marking, testing and evaluation of conformity

Steps shall be made from:

a) aluminium alloy to EN573:3 designation 6 060 or 6 106

b) cast iron – malleable conforming to EN1563 cast iron – spheroidal graphite (ductile) cast iron to EN1563 cast iron – flake graphite (grey) cast iron to EN1561

c) steel – to EN10025 or ENV10080 steel – austenitic stainless steel to EN10088-1 or EN10088-3, minimum grade X6CrNiTi18-10

Type D plastic encapsulated double steps are generally preferred. They are specified due to their high visibility, corrosion protection and durability

In most UK areas, single steps are not allowed. Single steps are considered less safe and those made from cast iron are prone to corrosion and increased risk of failure.

Steps are usually specified for manholes with a depth up to 3.0m from cover level to the soffit of the pipe.

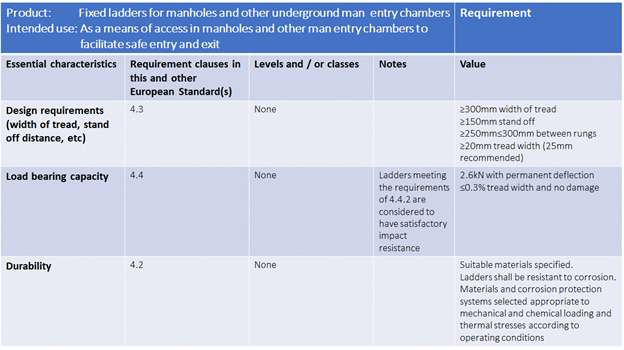

Ladders

BS EN14396:2004 Fixed ladders for manholes

Ladders are usually specified for manholes with a depth between 3.0m – 6.0m from cover level to the soffit of the pipe.

Steps and Ladders

Many designers and asset owners specify products that comply with the relevant Standards, sometimes with further requirements for CE marking, Kitemarking etc to assure reliable manufacture and product quality. The purchase decision is left to the installer. Products that comply with such Standards meet a minimum requirement and are intended to provide assurance that the construction is completed using components of an acceptable quality to satisfy the design specification.

In the United Kingdom, there are harmonised product Standards relating specifically to manhole steps and to fixed ladders. There are also Standards and industry specifications relating to manhole assemblies and Standards relating to complete drainage systems where requirements for manhole steps, ladders and associated access systems are included in the specification. For innovative products that fall outside the scope of these Standards, independent assessment and third-party certification is advised.

The requirements in some industry specifications may demand different values for steps and ladders than the minimum requirements of the product Standard; these can be more onerous than the product Standard or they can be less demanding. Industry specifications are also sometimes inconsistent with each other and it can be confusing trying to decide on a suitable value to apply to a design. In these situations, it is advisable to consult the contract documents and confirm with the client which specification should take precedent.

Standard Caswick steps and ladders comply with the relevant product Standards and carry CE marking and Kite marking accreditations where appropriate. Generally, Caswick steps and ladders perform above the minimum requirements of the product Standard.

Designers, developers and asset owners beware.

There is a spectrum of quality, even for product Standard-compliant products. Those that only marginally conform to minimum requirements can result in lower long term performance over the manhole asset lifetime.

In the case of steps and ladders, this could compromise safety and result in higher whole life (totex) costs when compared with products of a superior quality that have the potential to perform better, for longer.

Manholes are dangerous underground confined spaces. Only authorized personnel should have access with the knowledge, equipment and the security means to carry out relevant inspection and maintenance work. In the vast majority of cases, access is made once or twice a year for routine maintenance. Sometimes chambers are not visited for years, only when an incident occurs.

When the manhole cover is lifted, the steps or ladders found were probably installed when the system was built. Each step inside the chamber can be a leap of faith. Even for Standard-compliant products, over time steps and ladders made from lower quality materials may place operatives at higher risk. Deterioration is progressive; the risks may not be immediately apparent, but can become evident with age. Exceedance of minimum Standard requirements can therefore provide “future-proofing” to ensure satisfactory long term performance.

The steel used for Caswick manhole steps is high tensile steel to BS EN10305 Steel tubes for precision applications. It is the Standard for cold drawn steel tubes of circular cross section. The advantage of steel tubes for precision applications is the high accuracy of their manufacturing, the good quality of their surface and the guaranteed mechanical and technological properties.

that is why the tubes are widely used in the machining industry and in the automotive industry.

Lower quality steps are not made from high tensile steel and do not provide the same degree of dimensional stability and robustness.

Most Water Undertakers prefer plastic encapsulation for enhanced durability and corrosion protection. Standard Caswick manhole steps use a special grade Polypropylene encapsulation which provides greater protection from impact, mechanical and thermal stress cracking and ageing. The actual thickness of the plastic encapsulation for Caswick steps is generally in excess of 4 mm compared with a minimum requirement of 2.5mm (BS EN13101).

These factors are important because plastic becomes brittle and as it ages cracks can appear in the encapsulation. This can expose the metal underneath and lead to corrosion and potential failure of the step, over time.

- Steps

BS EN752 : 2017 Drain and sewer systems outside buildings. Sewer system management states

Manhole steps should not be used for access / egress in manholes deeper than 3.0m from cover level to the soffit of the pipe.

Manhole steps should be Type D Class I double steps conforming to BS EN13101 with a minimum tread width of 320mm.

Not less than 150mm foot room should be provided between the steps and the chamber wall behind them, when measured at the centre of the step.

Not less than 900mm of clear space should be provided on any landing between the face of the steps and any wall or handrail. This means that the minimum chamber size should be 150mm + 900mm = 1050mm.

Note that Sewers for Adoption requires that the minimum nominal internal dimension of a manhole is 1200mm. Therefore, a 1050mm chamber would not meet the requirements of Sewers for Adoption.

- Ladders

BS EN752 states

Fixed, corrosion resistant ladders conforming to BS EN14396 (or stairs) may be used in place of steps and should be used for depths over 3.0m.

Not less than 200mm foot room should be provided between the rungs of ladders and the chamber wall behind them, when measured from the centre of the step.

Stringers should be adequately supported from the manhole wall at intervals of not more than 3m.

Stringer supports should not be built into the wall but bolted to built-in cleats to facilitate renewal.

Steps and Ladders

With further reference to BS EN752, where ladders or steps are in use, a means of fall prevention should also be provided. In order to deter unauthorized access, some manholes are not fitted with permanent ladders or steps. In such cases, personnel are normally winched into and out of the manhole, however, an alternative means of rapidly removing personal including casualties from the manhole, should provided for use in an emergency.

The key product Standards are:

Steps

- BS EN13101 Steps for underground man entry chambers. Requirements, marking, testing and evaluation of conformity.

Ladders

- BS EN14396 Fixed ladders for manholes

Other industry Standards and specifications that cross-reference with the above and define requirements within an assembly or system include:

- BS EN752: 2017 Drain and sewer systems outside buildings. Sewer system management

- BS EN1610:2015 Construction and testing of drains and sewers

- BS EN476:2011 General requirements for components used in drains and sewers

- BS EN1917:2002 Concrete manholes and inspection chambers, unreinforced, steel fibre and reinforced

- BS5911-3:2014 Concrete pipes and ancillary concrete products. Part 3 Specification for unreinforced and reinforced concrete manholes and soakaways

- BS EN13598-2:2009 Plastics piping systems for non-pressure underground drainage and sewerage Part 2 Specification for manholes and inspection chambers in traffic areas and deep underground installations

- Sewers for Adoption 7h Edition

- Sewers for Scotland 3rd Edition

- Welsh Standards for new gravity foul sewers and lateral drains

- Sewers for Adoption Northern Ireland 1st Edition

- Civil Engineering Specification for the Water Industry 7th Edition (CESWI)

- Building Regulations 2010 Approved Document H Drainage and Waste Disposal

- Building Standards (Scotland) Part M Technical Handbook 2017

- Building Regulations Part N Northern Ireland

- Specification for Highways Works Series 500 Drainage

- Highway Construction Details (HCD)

In a changing environment, the list above is what is believed to be the current situation. If this information is not correct, your feedback with the correct reference material would be appreciated.

Many designers and asset owners specify products that comply with the relevant Standards and leave the purchase decision to the installer. Products that comply with such Standards meet a minimum requirement and are intended to provide assurance that the construction is completed using components of an acceptable quality to satisfy the design specification.

In the United Kingdom, there are harmonised product Standards relating specifically to manhole steps and to fixed ladders. There are also Standards and industry specifications relating to manhole assemblies and Standards relating to complete drainage systems where requirements for manhole steps, ladders and associated access systems are included in the specification. For innovative products that fall outside the scope of these Standards, independent assessment and third-party certification is advised.

Standard Caswick steps and ladders conform to the key product Standards. In most cases, other industry specifications require compliance with the key product Standard as a minimum. Additional requirements falling outside the Standards will need to be defined and agreed by the client noting that this may result in bespoke product design and manufacture with longer lead times and higher costs.

The requirements in some industry specifications may demand different values for steps and ladders than the minimum requirements of the product Standard; these can be more onerous than the product Standard or they can be less demanding. Industry specifications are also sometimes inconsistent with each other and it can be confusing trying to decide on a suitable value to apply to a design. In these situations, it is advisable to consult the contract documents and confirm with the client which specification should take precedent.

Under domestic law (the Health and Safety at Work etc Act 1974) employers are responsible for ensuring the safety of their employees and others. This responsibility is reinforced by regulations.

The Confined Spaces Regulations 1997

Apply where the assessment identifies risks of serious injury from work in confined spaces.

- These regulations contain the following key duties:

avoid entry to confined spaces, e.g. by doing the work from the outside; - if entry to a confined space is unavoidable, follow a safe system of work; and

- put in place adequate emergency arrangements before the work start

The Management of Health and Safety at Work Regulations 1999

Require employers and self-employed people to carry out a suitable and sufficient assessment of the risks for all work activities for the purpose of deciding what measures are necessary for safety. For work in confined spaces this means identifying the hazards present, assessing the risks and determining what precautions to take.

A confined space is a place which is substantially enclosed (though not always entirely) and which also has a reasonably foreseeable risk to workers of serious injury from hazardous substances or conditions within the space or nearby such as fire, explosion, loss of consciousness, asphyxiation or drowning. A confined space has limited or restricted means for entry or exit and is not designed for continuous occupancy. Confined spaces may include, but are not limited to, tanks, vessels, silos, storage bins, hoppers, vaults, pits, manholes, tunnels, access shafts, boilers, pump stations, digesters, water supply towers, equipment housings, ductwork, sewers, pipelines.

In general, a confined space is made up of 3 main parts:

1) being large enough for an employee to enter and perform work

2) has limited or restricted means for entry or exit

3) is not designed for continuous occupancy

Useful information:

Confined Spaces: A brief Guide to Working Safely

Guidance on permit-to-work systems: A guide for the petroleum, chemical and allied industries

Developers have a duty to appoint a principal designer in accordance with the Construction (Design and Management) Regulations 2015. The designer is responsible for all the duties described in the Regulations.

The Regulations require the principal designer to take into account (in addition to construction risks) the health and safety aspects over the whole life of the development.

The developer must include a management and maintenance plan (in addition to the health and safety file) to demonstrate that the designer has taken the health and safety considerations of future maintenance into account in preparing the design.